What is supply chain management?

Supply chain management is all about efficiently moving products from raw materials to customers’ hands. It covers every step: sourcing, production, storage, transport and delivery. Good supply chain management ensures products are available at the right time, in the right place and at the best cost. It also helps businesses stay competitive by cutting waste and adapting quickly to disruptions. Essentially, it is the backend magic that ensures businesses stay stocked, online orders arrive on time and industries keep running.

Supply chain refers to the processes that are involved in moving the products from the supplier to consumers. It is a network of organizations, people, resources, activities and information involved in upstream and downstream. Supply chain management (SCM) is the process of handling the flow of goods or services. The activities involved from acquiring raw materials to the final delivery of the product to consumers come under SCM. Supply chain management minimize the waste, cost and time consumed in the production process.

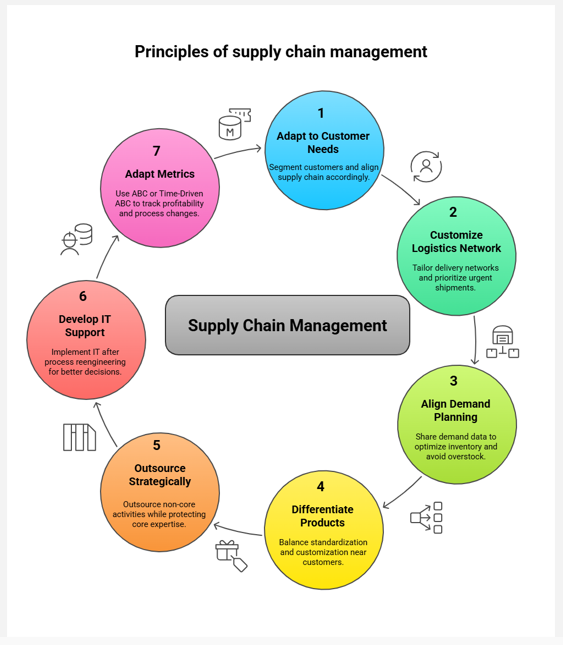

What Are the Principles of Supply Chain Management?

1. What Does It Mean to Adapt Supply Chain to Customer’s Needs?

The businesses and supply chain professionals understand customer’s needs. Customers are divided into different groups called ‘segments’ in order to understand them better. On the basis of sales volume or profitability, the primitive way to segment customer is ABC analysis. It can also be done by product, trade channel and industry. Anticipating the customer’s needs is also very important. Once the needs of the customers are anticipated, the supply chain should be aligned to cater to the needs.

2. How Can Businesses Customize the Logistics Network?

After the segmentation of the customers based on different requirements, SCM managers have to tailor logistics networks to serve different segments. The SCM manager has to prioritize the deliveries and make suitable provisions to quickly distribute those goods that are marked as urgent.

3. Why Is Aligning Demand Planning Important Across the Supply Chain?

Supply chain professionals are trained to share data with trading partners in order to avoid the unnecessary stock. The demand data must be used wisely by the SCM managers.

4. How Does Product Differentiation Benefit Customers?

Standardization and differentiation are two completely opposite things. Some cosmetic companies manufacture only 1 SKU that can be sold throughout Asia instead of 1 SKU per country. Due to the economy of the sales, standardization can drastically bring down the cost.

5. What Functions Should Be Outsourced Strategically?

Though outsourcing is all the rage, the managers must outsource strategically. The core expertise should not be outsourced ever. This principle stands the test of time.

6. How Do IT Systems Support Supply Chain Decision-Making?

The IT projects should not be done in isolation and before IT projects, the business process reengineering should be done. This provides a proper understanding of process insufficiencies and helps to determine the kind of innovation needed.

7. Why Should Companies Adapt Service and Financial Metrics?

The activity-based costing (ABC) is applied to determine the customer’s profitability. It is even better to exploit Time Driven Activity Based Costing in order to understand changes in activities, process, product and customers.

So, these were seven principles of supply chain management given by the experts of the field. A manager can be successful if he follows these principles in supply chain management. At MIT School of Distance Education (MIT-SDE), we offer Post Graduate Diploma in Business Administration (PGDBA) and Post Graduate Diploma in Management (PGDM) courses in Supply Chain Management equivalent to MBA distance education. Our course is a mix of practical and theoretical knowledge. We train all our candidates to effectively apply the concepts and principles in real life. So, if you want to enhance your employability skills then pursue distance MBA equivalent courses from MIT-SDE.