Operations management focuses on how organisations manage and enhance the systems that deliver goods and services. In today’s environment, these systems face constant pressure to be faster, more accurate, and more consistent. Meeting these demands requires technology at the core of every operational function. From production lines to logistics networks, and from data dashboards to customer fulfilment systems, every stage of operations is built on digital infrastructure.

As a result, the study of technology becomes a fundamental part of how modern operations are taught and applied. Students enrolling in online operations management courses are introduced to these technologies early, as they underpin real-world processes. For professionals aiming to enter or grow in this field, understanding these tools is essential for handling complexity, reducing costs, and making fast, informed decisions.

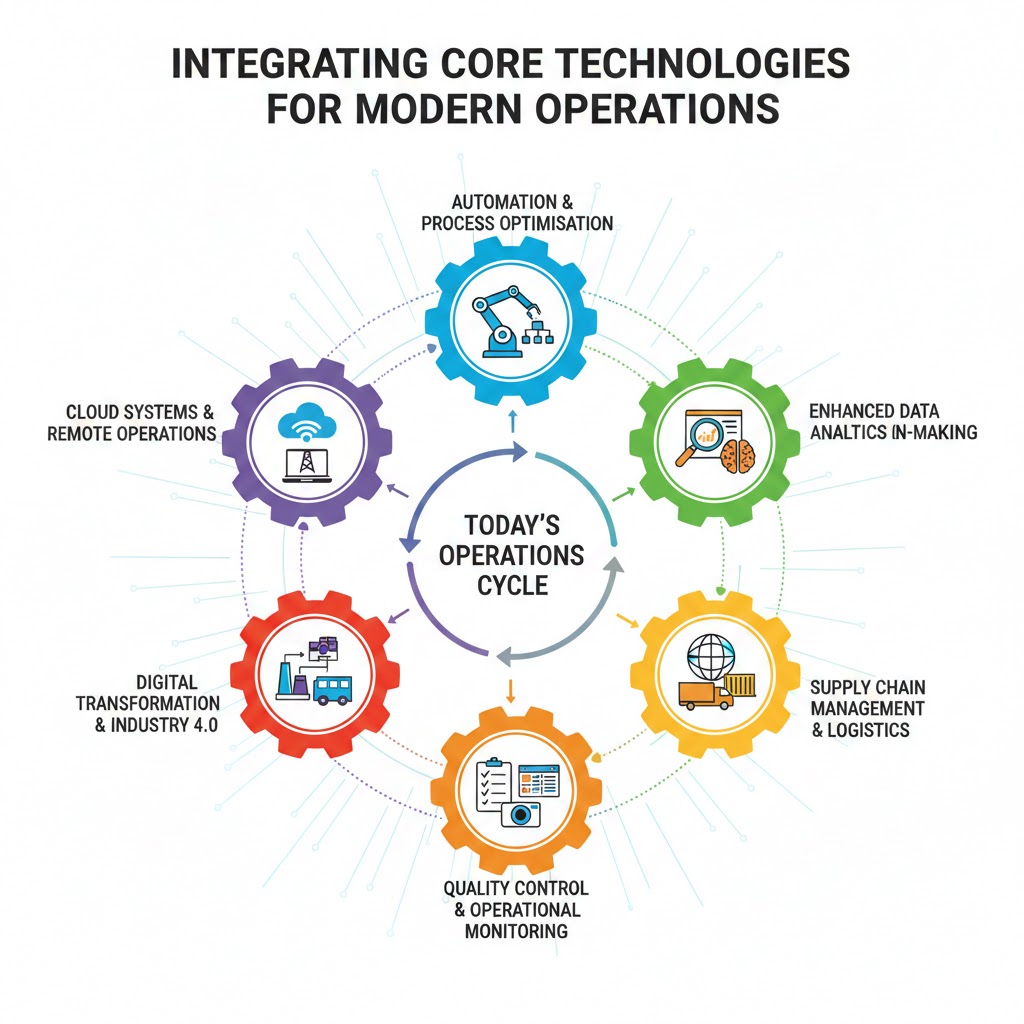

How each core technology area fits into today’s operations cycle

Automation and Process Optimisation

Automation enables repetitive, manual tasks to be performed with precision. These tasks include scheduling, data entry, batch processing, and even machinery control.

- Workflow automation reduces turnaround time in production

- Robotic Process Automation (RPA) handles back-office functions like order updates

- Scheduling tools assign resources based on availability and deadlines

This improves consistency and allows operations teams to focus on system design and oversight. As organisations scale, automation becomes necessary to maintain output quality and delivery timelines.

Enhanced Data Analytics and Decision-Making

Operations generate huge amounts of data every day — from production rates to shipment timelines. Data analytics helps teams convert this information into performance insights.

Here’s how different tools align with decision-making:

Tool Type | Function |

Dashboards | Real-time visibility into KPIs |

Forecasting Models | Predict demand, inventory, or delays |

Root-Cause Analysis Tools | Identify process-level inefficiencies |

When taught in online operations management courses, these tools help students learn to respond early to risks and improve long-term planning.

Supply Chain Management and Logistics Technologies

Managing the movement of materials is a core part of operations. Technology brings traceability and structure to these flows.

- RFID tracks materials through production and warehouse stages

- GPS provides live visibility into vehicle movement and delivery status

- Blockchain ensures security and trust in supplier transactions

- Supplier portals streamline order tracking and communication

These systems prevent shortages, delays, and miscommunication — making supply chains more stable and efficient.

When Should Quality Control and Monitoring Be Implemented?

Maintaining product and service quality requires real-time monitoring. Technology supports this by detecting irregularities before they affect output.

- Sensors installed on equipment monitor temperature, vibration, and pressure

- Quality inspection systems verify product dimensions or specifications

- Monitoring software compares batch data to target values

This continuous tracking enables faster corrections and fewer errors in the output. It directly impacts customer satisfaction and cost efficiency.

Digital Transformation and Industry 4.0

Industry 4.0 introduces the integration of digital systems across all stages of operations. This includes simulation tools, digital twins, and IoT devices that support smart factories.

- Digital twins simulate production lines for testing before implementation

- IoT sensors collect data from multiple machines for predictive analysis

- Intelligent dashboards help teams adjust operations in real-time

These capabilities are core to most case studies and projects in the top online diploma in operations management, as they reflect how modern firms run live operations.

The IoT in manufacturing market is expected to expand from ~$141 billion in 2025 to over $1.1 trillion by 2034, showing huge adoption of connected devices across industrial operations.

What Are Cloud Systems and Remote Operations?

Cloud technology enables operations teams to work across locations and access real-time information from any device.

- Inventory systems, supplier dashboards, and reporting tools run in the cloud

- Managers can track performance, approve workflows, and flag risks remotely

- Cloud tools support continuity even during disruptions

This flexibility has become essential in globally distributed businesses and is covered in detail within technology in operations management modules.

Closing Thoughts!

Technology allows operations managers to monitor, control, and improve every element of the delivery process.

For learners and working professionals, gaining confidence in these tools through structured learning is key. Programmes built around technology in operations management provide the context and skills needed to step into roles with real operational responsibility.